Advanced Composite Solutions

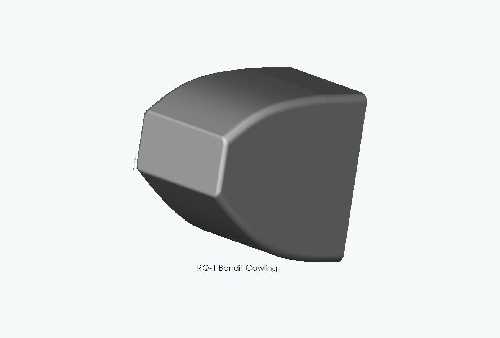

The use of composite materials for aircraft structural applications continues to expand within the aerospace industry and is especially useful in the RPAS/UAS industry. Composite parts are almost the exclusive solution for prototype and production aircraft, both unmanned and manned. Composite tooling for prototype and low rate production composite parts is a cost-effective solution for rapid prototyping.

GT Aeronautics takes great pride in providing the highest quality composite tooling and composite parts to fulfill your prototype and production needs. After a quick consultation with one of our staff, we can quickly determine the most cost-effective composite solution to suit your application.

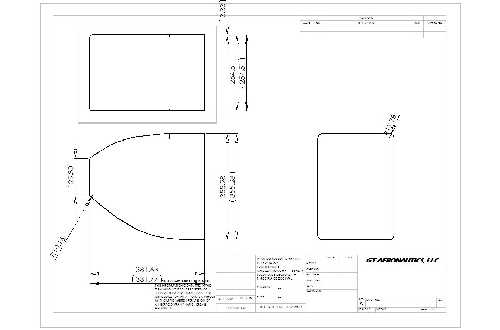

We will create tooling made to your specifications and in a very short time provide you with the highest quality custom composite parts available. Best of all, you can determine the materials used in the production of your part so that it satisfies your structural requirements.

Manufacturing Standards

GT Aeronautics follows strict manufacturing procedures during production of composite parts to ensure the highest quality. All of our composite parts are produced under vacuum (as high as 28" Hg) and heat cured to provide the lightest, strongest, most durable parts available.

Both wet layups and prepreg layups are available with a nearly infinite combination of materials. Typical composite fabrics include E-Glass, S-glass, Carbon Fiber, and Kevlar. Typical core materials include Rohacell, Structure Foam, End-grain Balsa, Aeromat, and Hexcell. Gelcoat and primed exteriors are also available.